Touch ‘N Foam Professional® Wall & Cavity Foam with Widespray Applicator kits are portable, self-contained one-component polyurethane foam dispensing kits. When used according to manufacturer’s directions, they effectively air seal and insulate homes and buildings while enhancing R-Value and providing Class A fire resistance. The patent-pending technology offers a broadcast spray solution similar to two-component systems, but in a less complicated, easier to use one-component solution. This one-component system can be applied in a wide temperature range of 40°F - 120°F. Great for repairs, renovations and new installations. Not to be used for direct overhead spraying applications.

Key Features

-

CLASS A FIRE RESISTANT

-

SAVES ENERGY

- Pre-mixed formula that is always on ratio

- Portable and easy to set up

- Responsive wide spray applicator that can spray horizontally and vertically

- Wide temperature range (40F - 120F) for greater project versatility

- Great for filling wall cavities, rim joists, attic & crawl spaces (excludes overhead spraying)

- Class A fire rated

- Save on energy costs

- High closed cell content

- Interior use only

- Low Global Warning Potential

- Air seals

How to Use

PREPARATION & APPLICATION

Proper application is crucial to getting the best performance out of your Wall & Cavity Canister Foam. Please review these steps before beginning work on your project.

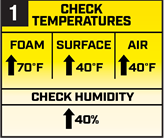

Step one: Check 3 temperatures & relative humidity before applying.

Step two: Shake canister vigorously (by holding the top and bottom of the tank) for at least 30 seconds.

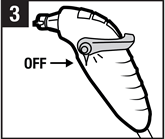

Step three: Make sure the lever on application is in OFF/closed position.

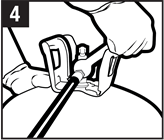

Step four: ATTACH HOSE finger tight and then use the wrench provided to tighten additional 1/4 turn.

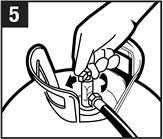

Step five: 3 full turns; Fully open the valve on tank by turning three times (360°).

Step six: Test spray on test cardboard or into trash bin before use on project to get a feel for the flow.

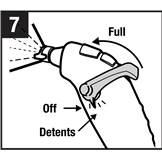

Step seven: Slowly push trigger forward to first detent to open valve to dispense foam. Increase flow by pushing forward to third detent.

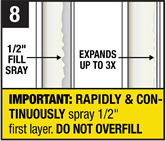

Step eight: Foam expands up to 3x. Spraying more than 1/2" can lead to slumping or drooling foam.

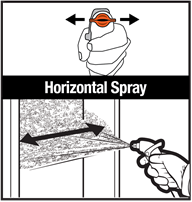

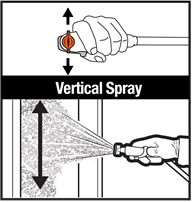

HORIZONTAL & VERTICAL APPLICATION

The applicator sprays HORIZONTALLY when nozzle is in horizontal position. To spray VERTICALLY, rotate hand so that the nozzle is in the vertical position.